for Mattresses

Ultraflex is a new, specifically developed high performance version of SpringBond®

Created through detailed research and development utilising a blend of cutting-edge fibres, at the forefront of the non wovens industry.

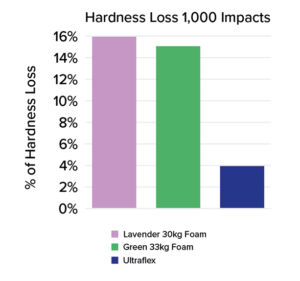

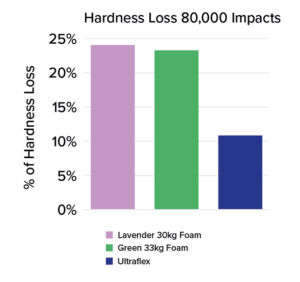

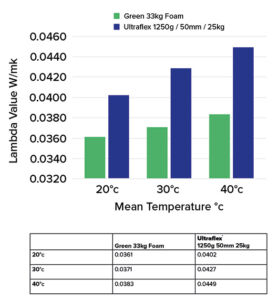

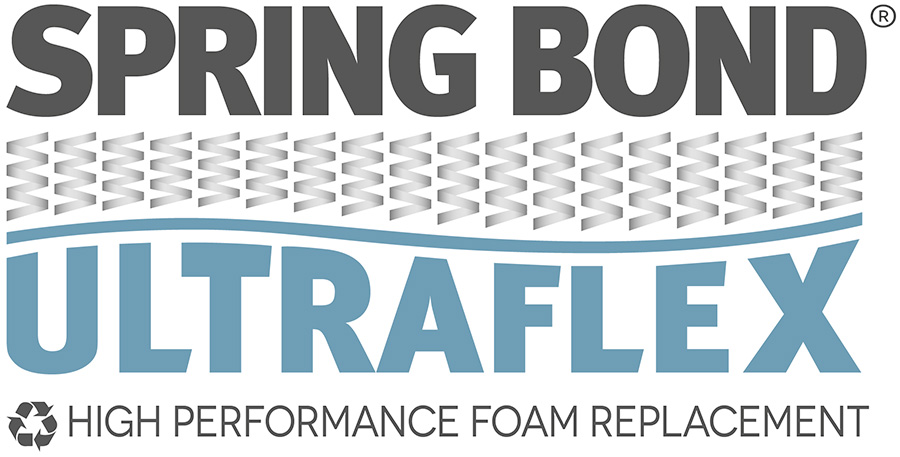

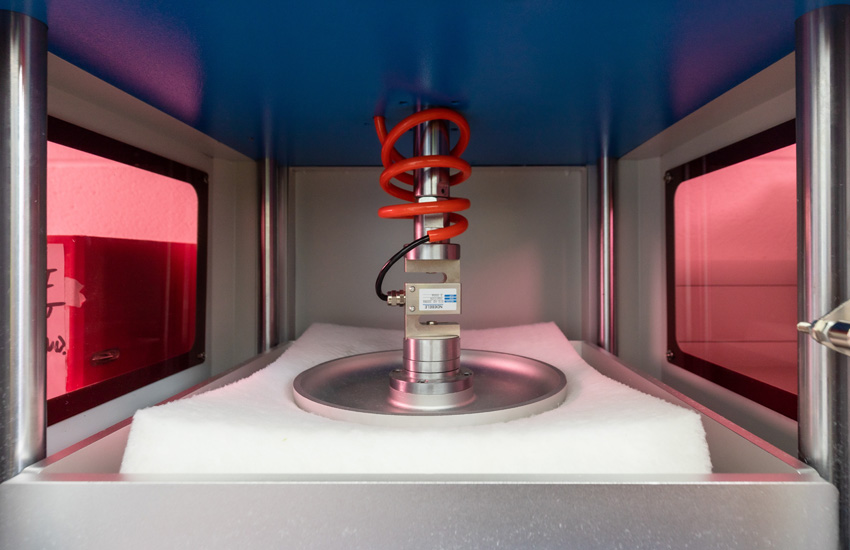

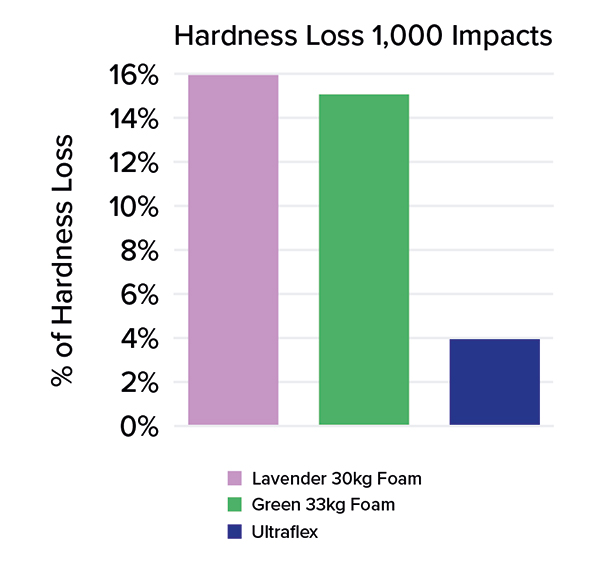

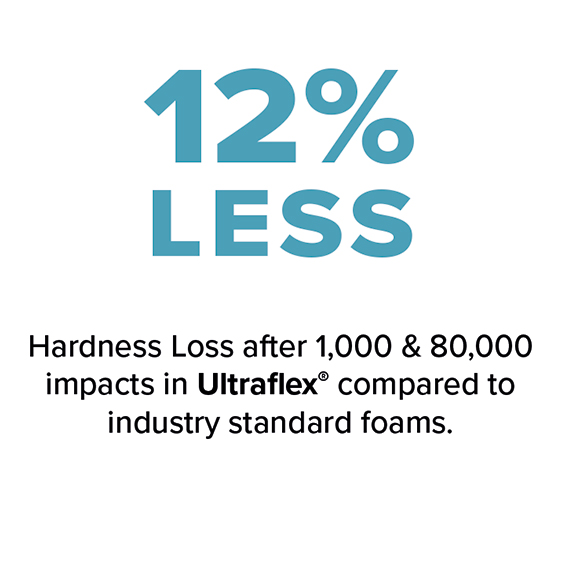

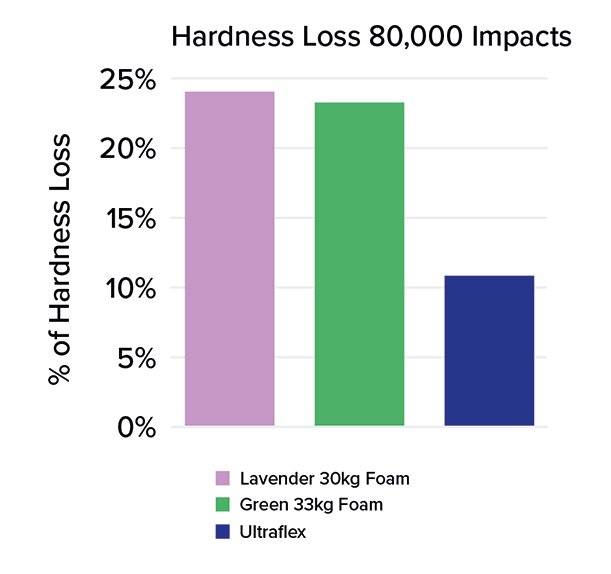

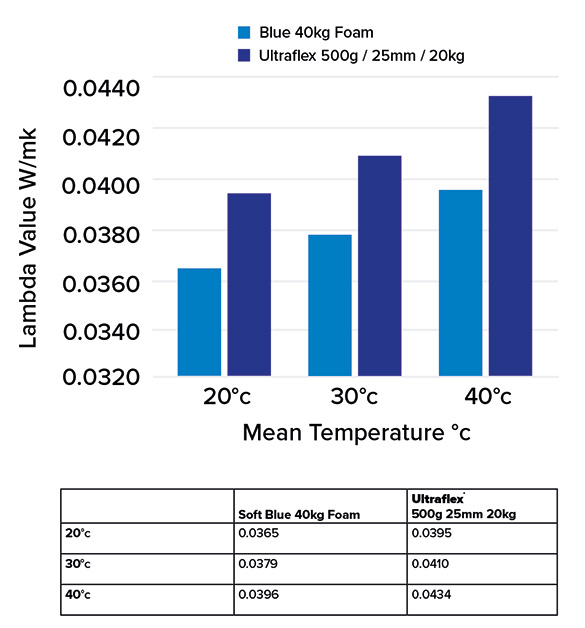

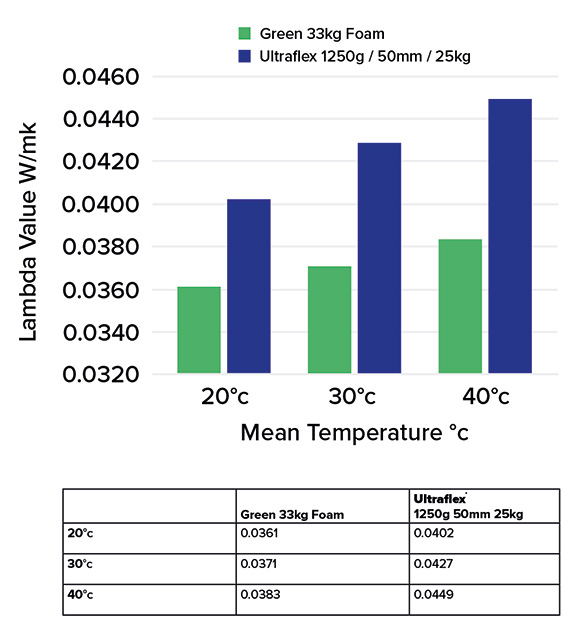

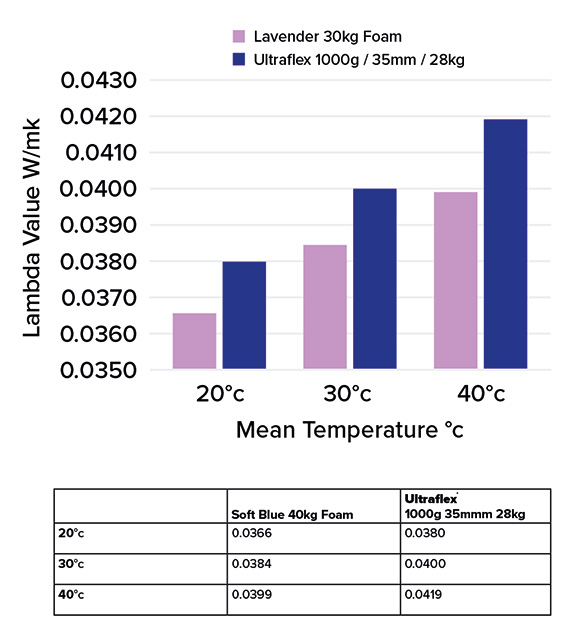

It’s been widely referred to in the industry as a ‘revolutionary, game changing’ alternative to PU foam. Using next generation performance fibres, carefully engineered in a sweeping ‘s’ shape structure to provide unrivalled rebound, comfort & long lasting performance, typically out performing commensurate foams in hardness loss testing. SpringBond® Ultraflex is proven to out perform PU foam

SpringBond® Ultraflex

SpringBond® Ultraflex provides manufacturers with all the features and benefits of SpringBond®

REBOUND & RECOVERY

For long lasting comfort & performance

FLAME RESISTANT

Needs no additional FR chemicals (BS5852 Schedule 2 part 1 shd/pt)

HYPO-ALLERGENIC

Dust free and no degradation

CHEMICAL FREE

Less harm to the environment and end user

SAFE

No harmful VOCs, better for indoor air quality (BS EN ISO 10580:2012)

BREATHABLE

The porous non-woven structure offers increased breathability

BRITISH MADE

Smaller carbon footprint

100% RECYCLABLE

Cradle to cradle inspired design

Why choose SpringBond®?

Technically advanced non-woven, manufactured from up to 80% regenerated fibres in a unique ‘s’ shaped structure that enhances performance, resilience and support in long term use. Designed to replace PU foam in wadding and cushioning for arms in sofas, chairs and headboards and a perfect solution for insulator pads in spring units. SpringBond® is offered in various thickness and widths as standard and can also be offered in custom sizes.

British Made Smaller carbon footprint

Chemical Free Less harm to the environment

80% Recycled GRS compliant

100% Recyclable - Cradle to cradle inspired design

SpringBond® is greener

The polyester fibres used in SpringBond® are mainly derived from recycled single use plastic bottles – a true example of a circular product as it can be recycled again and again. Production of recycled PET uses 59% less energy* and reduces C02 emissions by 32%** compared to virgin polyester. The SpringBond® carbon footprint is further reduced by being British made in an efficient, environmentally friendly manufacturing plant, based in Yorkshire which uses up to 70% solar and green energy.

Video Case Studies

If you have a question about Springbond® or would like to find out more about the product and where to buy it from, then please get in touch.

info@texfelt.co.uk +44 (0)1274 905411

We’re on a mission to create sustainable products that make a difference to our planet.